Blog Detail

ERP Software for Chemical Industry: Key Insights and Benefits

Smarter Processes with Chemical Manufacturing ERP Software

The chemical industry is marked by strict rules, dangerous materials, complex processes and market demands. To manage these challenges efficiently, companies are turning to ERP software for chemical industry operations. These special systems help manufacturers to streamline production, ensure compliance and make data-operated decisions in the organization. Let us find out the major insight and tangible benefits of implementing an ERP system for chemical manufacturing, especially for businesses that are constantly looking at the scale.

1. Understanding ERP software for chemical industry operations

Unlike generic ERP systems, chemical manufacturing ERP software is designed to support industry-specific needs such as batch processing, formula management and regulatory compliance. It provides centralized control in procurement, production, inventory and quality assurance.

The chemical production process includes detailed tracking of raw materials, real-time visibility in operation and safe handling of substances. A customized ERP for chemical manufacturing can simplify these functions through automation and integration.

Major capabilities include:

By streamlining these important areas, chemical manufacturers can reduce waste, prevent production errors and improve operational agility.

2. Compliance and quality control: ERP's key features for chemical manufacturing

Regulatory compliance in chemical production is a top priority. Businesses should follow strict security and environmental rules. A well-designed ERP for chemical industry automatically tracks compliance and documentation, reducing the risk of penalties.

In addition to compliance, quality control is integrated deeply into the chemical manufacturing ERP system. Each stage of production can be monitored, tested and verified for quality before proceeding.

Some benefits include:

An ERP system for chemical manufacture helps to ensure stability in product quality, creates customer trust and reduces liability risks.

3. Inventory and supply chain adaptation with chemical manufacturing ERP software

Managing inventory in the chemical industry is more complex than in other areas. Materials may have limited shelf life, specific storage conditions may be required, or there may be safety threats. Here, strong chemical manufacturing ERP software helps companies to optimize storage and manage purchases effectively.

Inventory-related benefits of ERP:

In terms of supply chain, ERP provides better vendor coordination, delivery tracking and demand forecasting. With an associated ERP for chemical manufacturers, companies can reduce additional inventory, prevent stockouts and reduce delays.

The overall result is a more efficient and cost-effective supply chain that is adapted to quickly changing demands and market conditions.

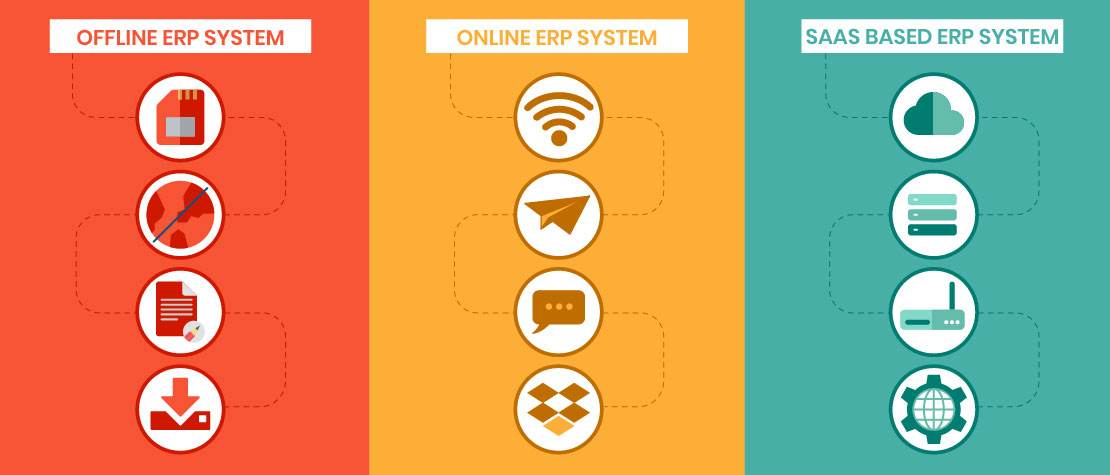

4. Role of cloud ERP software in India’s growing chemical sector

India is becoming a major centre for chemical manufacturing and businesses are adopting cloud ERP software in India to remain competitive. The cloud-based ERP offers flexible deployment, quick updates and low infrastructure costs, making it ideal for small to medium-sized manufacturers.

Why are more companies switching to cloud ERP:

With the adoption of cloud ERP software in India, manufacturers gain real-time visibility and collaborative abilities in geographically disseminated teams. This agility is particularly valuable in a rapidly evolving sector like chemicals.

5. Choosing the best ERP for chemical manufacturing: What to see

Choosing the best ERP for chemical manufacturing requires a solution that fits your specific business workflows. Look for ERP systems that provide chemical-focused features, scalability and vendor support.

Things to consider while choosing ERP solution:

An experienced ERP software company in India ensures that you get industry-specific facilities, backed by local support. A good ERP software for manufacturing industry should provide everything from inventory control to financial integration in a user-friendly package.

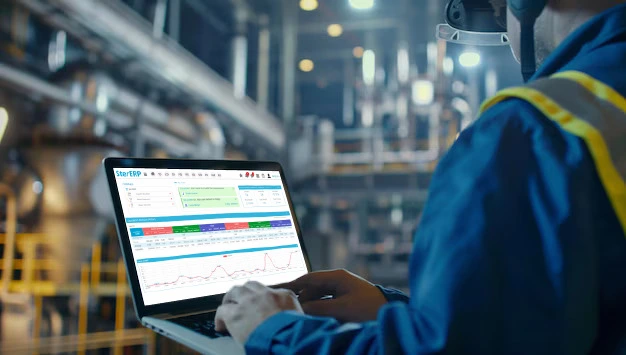

6. How ERP software enhances decision making and business development

ERP software has a strategic function in decision-making and it is not only about operation. A chemical manufacturing ERP consolves commercial data, which provides performance, profitability and real-time insights into areas.

Executives and managers can make faster, better-informed decisions based on live dashboard and KPI reports. From monitoring raw material costs to identifying high performing products, the ERP software enables smarter planning and rapid responses to market changes.

Additional benefits include:

With such devices, companies can move beyond day-to-day management and focus on innovation, expansion and permanent growth. It is the power of ERP software for chemical industry solutions.

Why choose TheERPHub for your chemical ERP needs

In the complex and competitive scenario of chemical manufacture, using the right ERP solution is essential for long-term success. A dedicated ERP for chemical manufacturing can help you reduce operational costs, increase product quality and ensure complete compliance with rules.

TheERPHub provides customized chemical manufacturing ERP software designed for specific challenges faced by the chemical industry. As a reliable ERP software company in India, we provide scalable, cloud-based and fully integrated solutions that provide real-time control and unmatched reliability.

Whether you're a growing manufacturer or a well-established enterprise, TheERPHub ensures you get the best ERP for chemical manufacturing backed by expert support and continuous innovation.

Are you ready to optimize your chemical manufacturing business with powerful ERP tools? Contact us today for a consultation.