ERP Software Features

Insightful Reports, Discover The Beauty Of Data

Gain more profound visibility into your business with our cloud-based ERP software features designed to turn complex data into clear, actionable insights. Our ERP solution helps you understand performance, trends and outcomes through visually rich and easy-to-read reports that support smarter decision-making.

With powerful ERP features built into the system, businesses can track operations, monitor growth and respond quickly to changes. These software features ensure that data is not just collected but presented in a meaningful way that helps teams stay aligned and informed at every level.

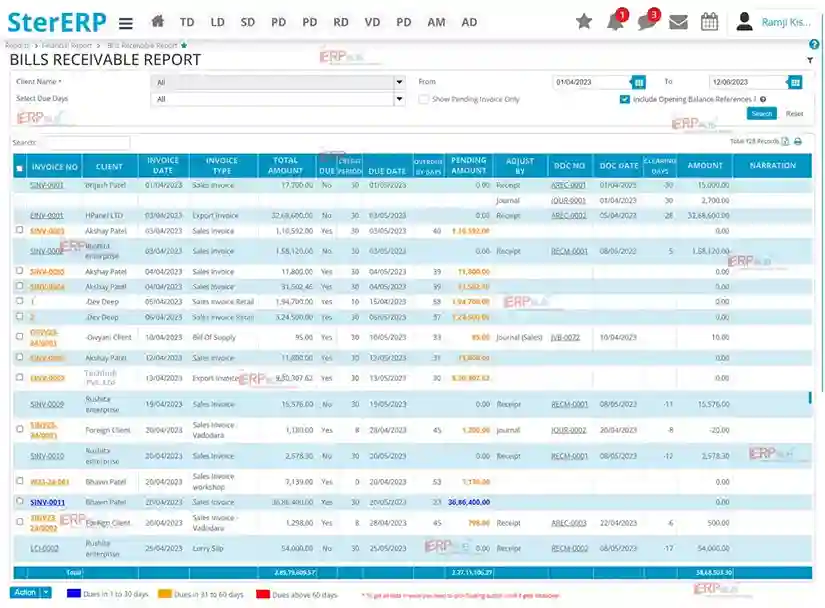

Bill's Receivable

The system provides a comprehensive display of sales invoice amounts, including their credit period and overdue days. Additionally, it presents adjusted vouchers with information on their clearing days and pending amounts. The system also generates an aging report with color coding for easy interpretation. Moreover, it offers the convenience of generating receipts directly from the form itself. Furthermore, the system has a built-in feature that allows the aging report to be displayed with colored visuals.

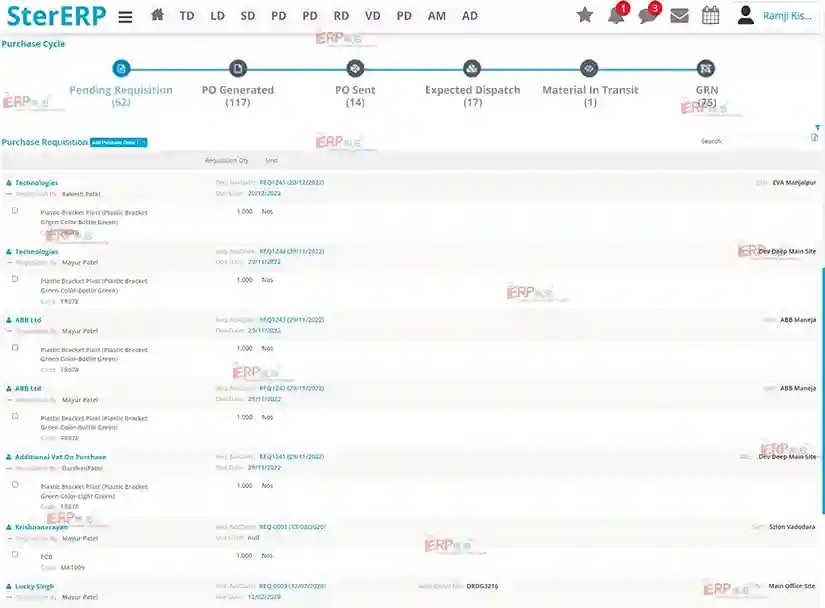

Purchase Cycle

An integrated solution with a unified view and action screen to effectively manage the entire purchase cycle. Seamlessly handle processes from purchase requisition to material transit, culminating in goods receipt. Enhance efficiency and control with streamlined workflows.

Delivery Performance Report

The consolidated sales order view offers a single-screen display of sales order details, open order details, commitment dates, dispatch information, and Hit or Miss status based on customer delivery dates per material. It also includes pending sales order data and provides a total hit metric to assess dispatch performance. This comprehensive view streamlines order management and enhances decision-making.

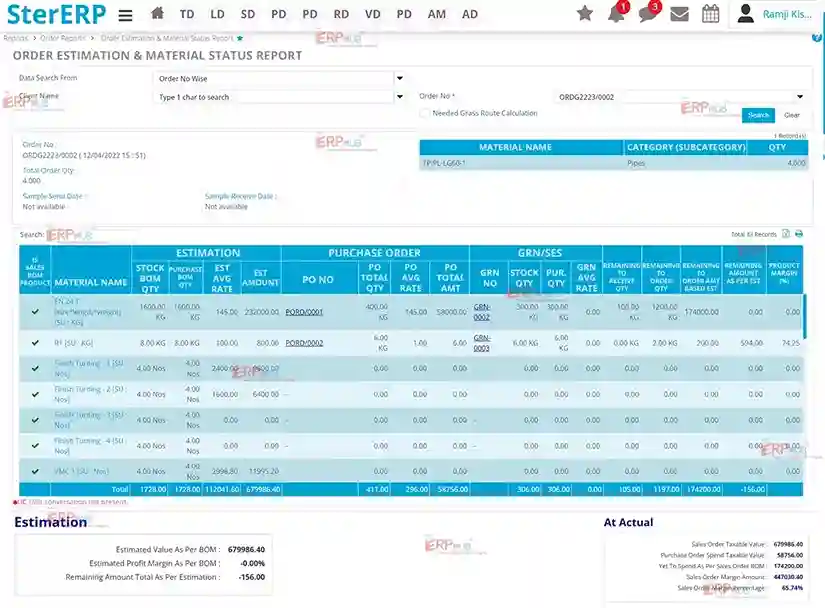

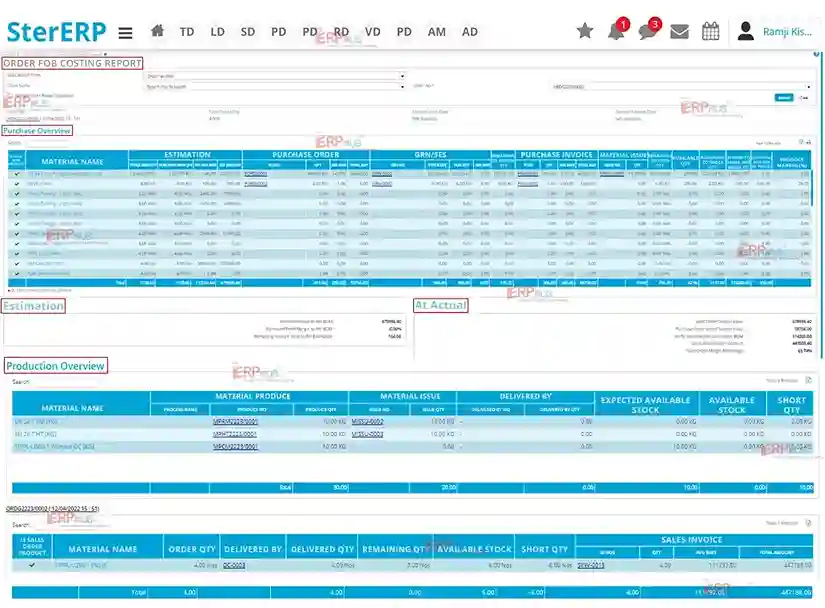

Order Estimation Report

The estimation for a sales order is calculated based on the connected Bill of Material (BOM). The system displays relevant details such as Purchase Orders raised for each BOM, materials received against the BOM, and the remaining quantities to be ordered and received. This consolidated view also presents the profit or loss against each material in the BOM and the overall profit for the entire order, allowing users to assess the estimation's alignment with the current profit status.

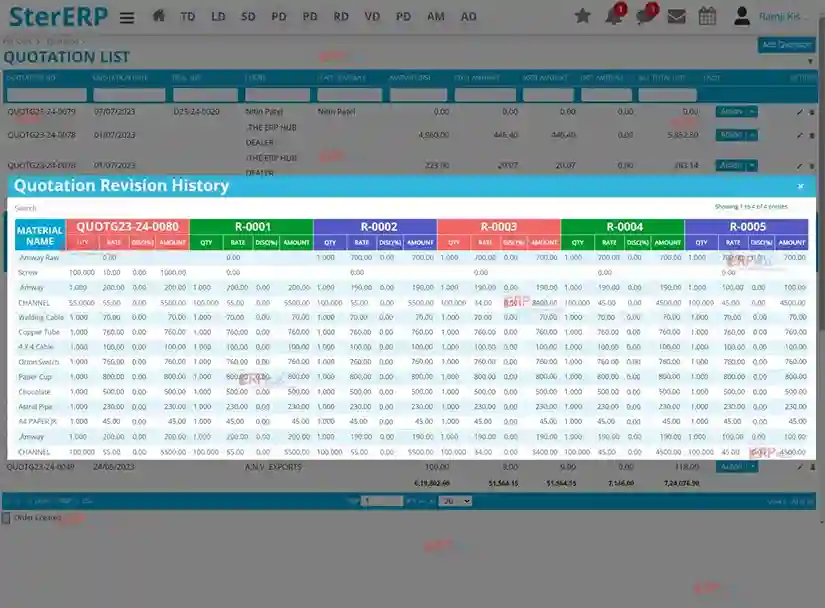

Quotation Revision History

In various business settings, sending multiple quotations for negotiation is standard practice. The Revision history feature provides a comprehensive view of material-wise negotiations, displaying discounts and amounts for each quotation on a single screen. It offers an overview of the deal's progress, showing date-wise changes in material quantity, discount, and total amount for each quotation.

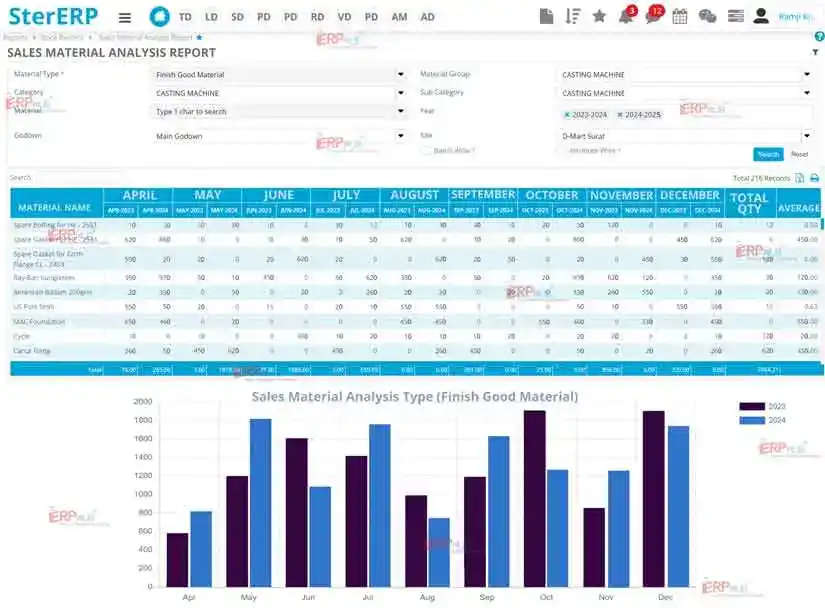

Sales Material Analysis Report

The sales analysis report provides a monthly overview of product sales, presenting material-wise data with multi-year comparisons. Users can apply filters based on material type, group, category, sub-category, and godown. The report also generates charts that offer visual comparisons based on the selected filters.

Order FOB (End to End Overview)

A powerful single-screen display that encompasses customized BOM data, including estimations, purchase orders (POs), goods receipt notes (GRNs), material consumption in production, material production, delivery challans, sales invoices, inventory status, and pending production. Streamline your workflow and gain comprehensive visibility into your entire production and sales cycle.

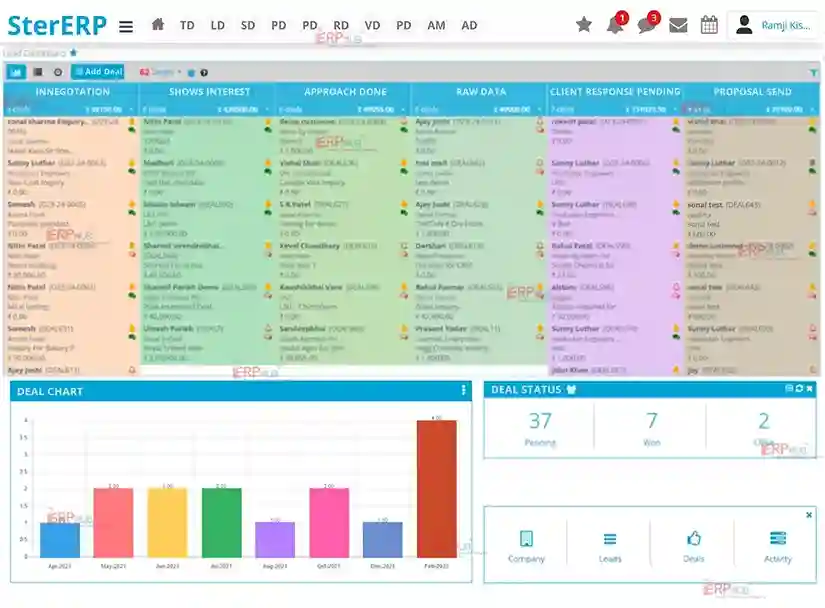

Lead (Inquiry / Deal management System)

Experience efficient inquiry management with built-in features such as follow-ups, comments, and versatile views like single-click pipe view, table view, and timeline view. Enjoy flexible data loading options based on individual, hierarchical, or all user rights, enhancing your workflow and organization.

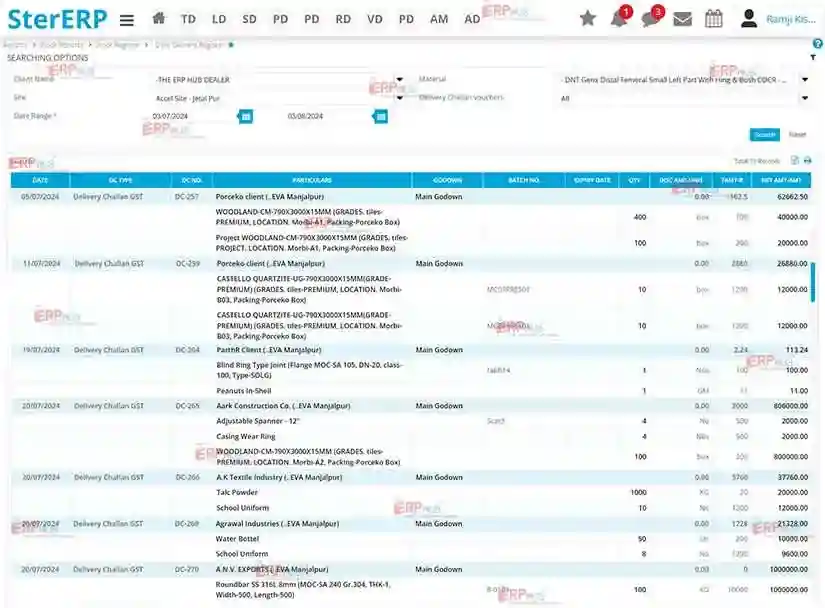

Delivery Register

The system provides detailed information on material outward transactions. Each transaction is displayed date by date and voucher by voucher, including essential details such as batch number, expiry date, and amount. Users can apply various filters, such as client name, material type, voucher type, and specific date ranges to refine the search results. This enables users to easily see the total quantity delivered over a selected period. Additionally, the system allows for in-depth analysis and tracking of material movements, ensuring accuracy and efficiency in inventory management.

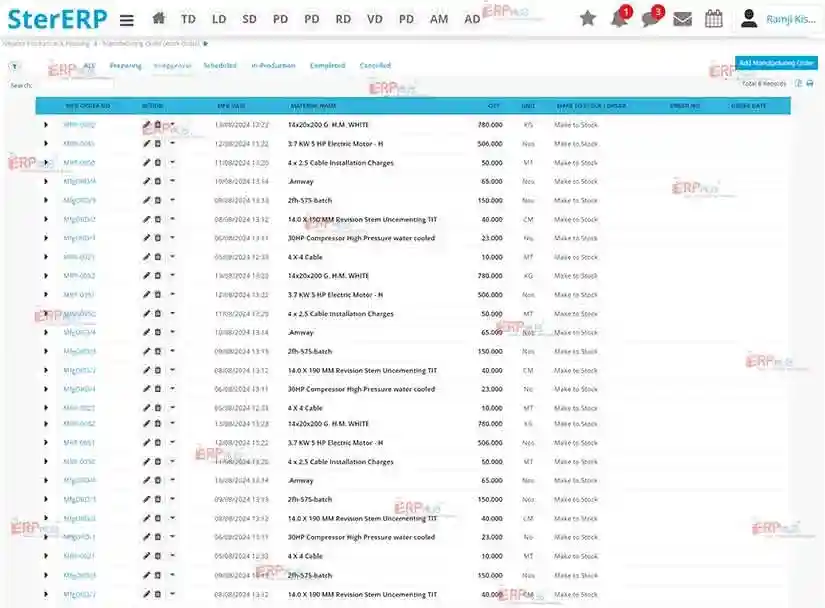

Manufacturing Order

Create Manufacturing Orders using Make to Stock, Make to Order, or Make to MRP options. The process includes workstation scheduling, labor scheduling, and material procurement, all accessible with a single click. Manufacturing Orders automatically derive overhead costs, material costs, process costs, and labor costs. The system supports recursive sub-order generation based on a hierarchical BOM structure. Once an order is saved, it can proceed to approval; upon approval, it gets scheduled for production. Additionally, users have the option to cancel the manufacturing order if needed.

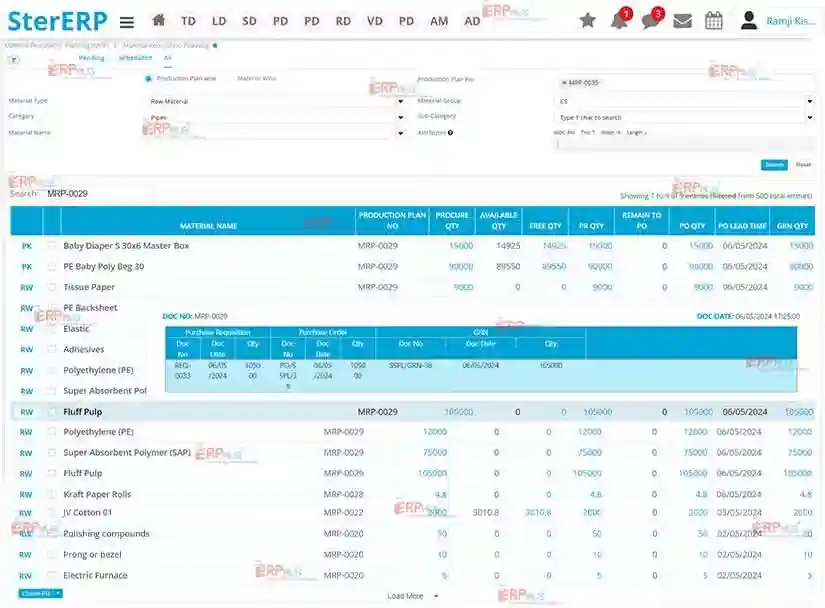

Material Requistion Planning

Production Planning can be generated using Make to Stock or Make to Order options. The Production Plan integrates with the BOM; once the BOM is generated, the finalized requirements can be determined. This allows locking the existing inventory, with the remainder going for procurement. Purchase Requisitions can be generated effortlessly with a simple tick mark. The progress of every plan can be tracked on a single screen, displaying the current status of materials, such as PR Raised, PO Raised, GRN received, etc.

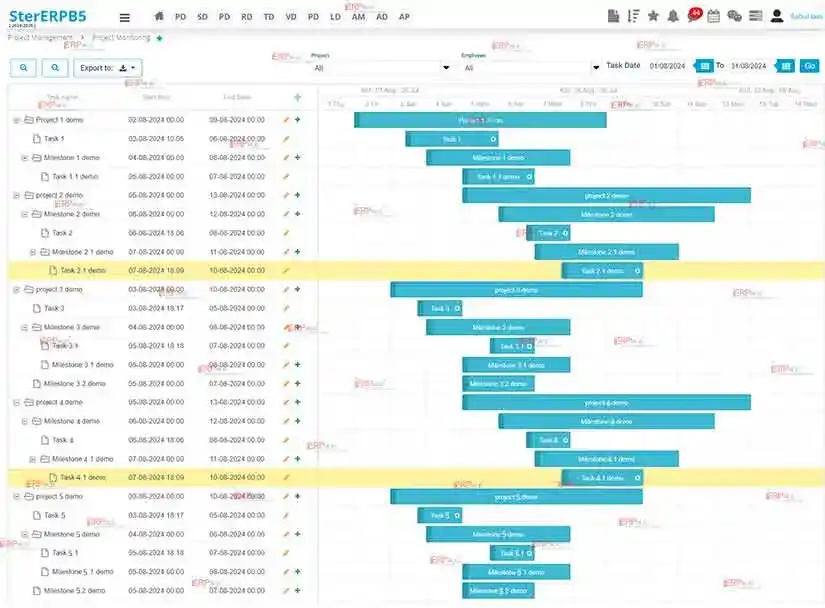

Project Monitoring

Our Project Monitoring feature with Gantt Charts provides a clear, visual timeline of your project’s tasks and milestones. It allows you to track progress, identify potential bottlenecks, and ensure that your project stays on schedule. With real-time updates, you can make informed decisions to keep your project on track and achieve your goals efficiently.

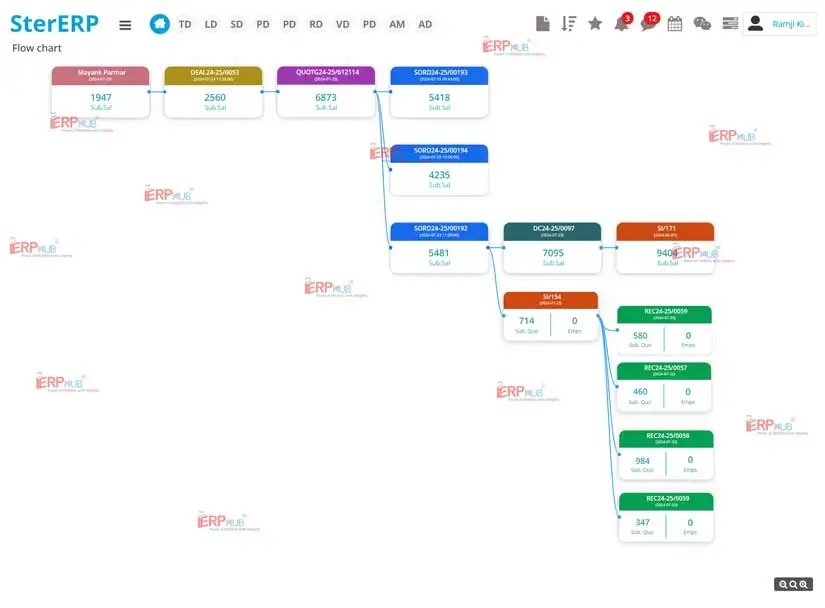

Flow Chart - Voucher

Our voucher flowchart provides clear visual guidance through the voucher lifecycle, from initial creation to final current position. This feature allows users to view voucher status at any stage, providing transparency and simplifying transactions. It enables vouchers to be efficiently managed in real time, by simplifying complex workflows.

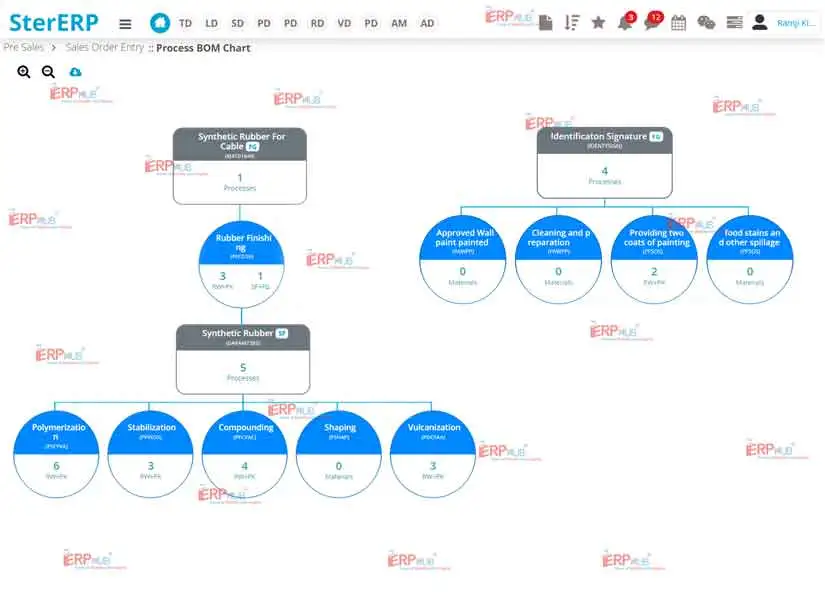

Process BOM Chart

The process BOM Flow Chart provides a detailed visual representation of the Bill of Materials process. It guides users through every step, from the initial listingof products to the final production, ensuring accuracy and precision in manufacturing. This tool increases efficiency by providing a clear visualization of the entire BOM workflow, making it easier to manage and manage production processes more efficiently.

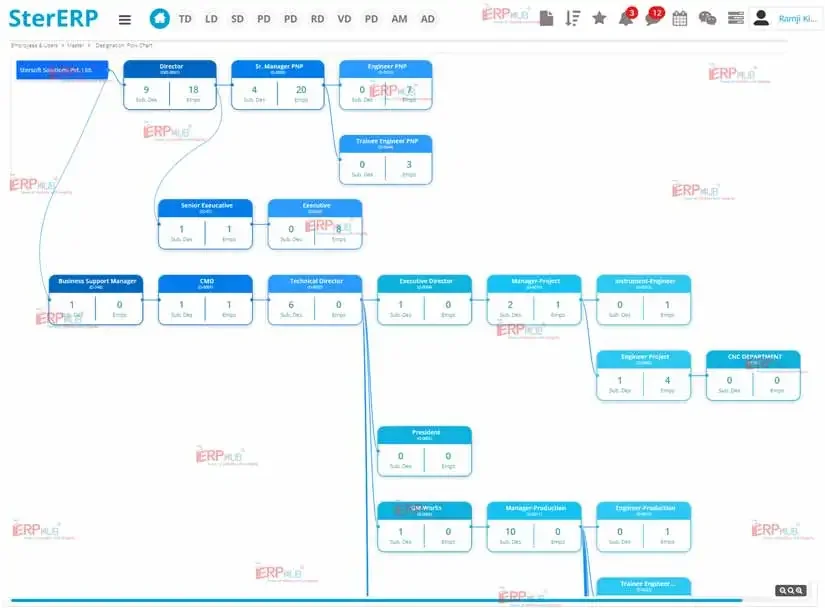

Organization Structure

A well-defined organizational structure is essential for smooth operations and effective communication. It outlines the roles, responsibilities, and reporting line within the company, ensuring clarity and accountability. Implementing a robust structure enables businesses to boost productivity, foster teamwork, and achieve their strategic goals.