Blog Detail

How advanced planning and scheduling software transforms shop floor operations

Transform your production with advanced planning and scheduling software.

In today’s competitive manufacturing environment, operational efficiency and timely delivery are important for commercial success. Advanced Planning and Scheduling (APS) software has become a transformative tool for shop floor operations. By integrating real-time data, intelligent algorithms and resource management, APS lets manufacturers plan, schedule and execute the production with accuracy. Coupled with ERP solutions, APS ensures that the operation of the shop floor has been adapted, flexible and aligned with commercial goals.

1. Streamlining production with advanced planning and scheduling software

Advanced planning and scheduling software helps manufacturers to create a detailed production program, considering obstacles such as machine capacity, content availability and barriers. By generating an exact schedule, it reduces downtime and increases workflow efficiency. Manufacturers can imagine the production stages, estimate issues and prevent delays before they occur.

The flexibility given by the APS allows the operation to quickly adapt to the sudden change in demand or supply. This adaptability ensures timely distribution of products while maintaining operational stability. Companies implementing the best advanced planning and scheduling software often see a solid decrease in lead time, higher throughput and improved customer satisfaction.

In addition, APS supports long-term plans by predicting the requirements of production based on historical data and market demand. This allows managers to effectively allocate resources, prevent bottlenecks and maintain smooth operations that align with strategic business purposes.

2. Enhancing visibility and control over the shop floor

One of the standout benefits of APS is the enhanced visibility it provides. Managers can monitor production progress, machine use and workforce performance in real time, eliminate manual tracking or the requirement of old reports.

Major benefits of APS include:

By integrating APS with cloud-based ERP for manufacturing, manufacturers can centralize data and improve decision-making in departments. This integration ensures that production schedules, inventory levels and customer orders are coordinated, which creates a spontaneous flow of efficiency information.

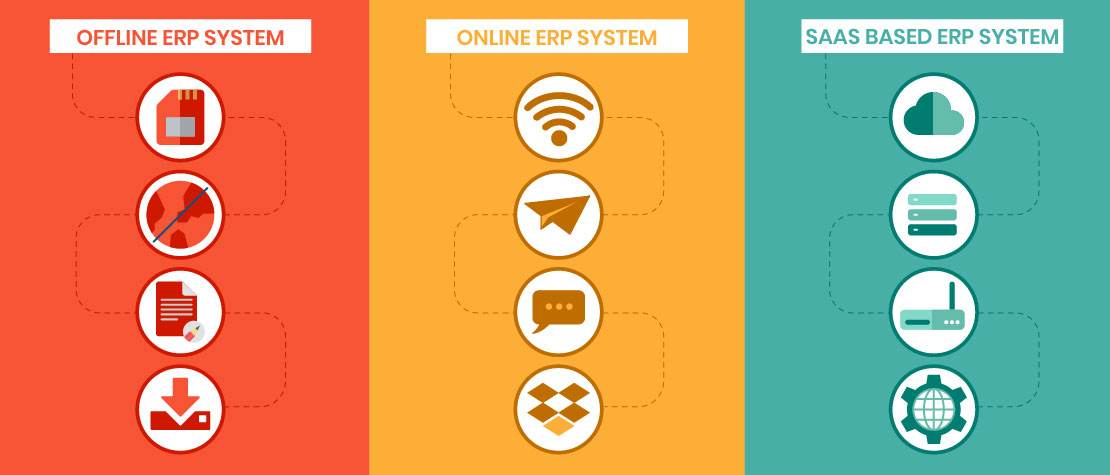

3. Integrating cloud-based ERP for manufacturing

Cloud-based ERP systems increase the power of APS by providing centralized, scalable and safe data management. With cloud-based ERP, manufacturers can access production data, reports and analytics from any location, which can enable quick decision making and better operational control.

The benefits of combining APS with cloud-based ERP include:

By using TheERPHub’s ERP solutions, manufacturers can basically integrate APS into existing processes, adapt to shop floor operations by reducing manual errors. Cloud-based systems also provide scalability, allowing businesses to grow without changes in major infrastructure.

4. Production scheduling optimization with APS

Production scheduling is one of the most important aspects of manufacturing. APS software allows managers to create realistic schedules that consider the availability of real machine capabilities, labor shifts and material availability. Unlike traditional scheduling methods, APS accounts for multiple variables, which ensure possible and efficient production schemes.

Some major scheduling benefits include:

By aligning the schedule with real-time shop floor data, manufacturers can prevent delays, reduce passive time and increase overall productivity. APS ensures that production remains tight and responsible even in the changing conditions in the market.

5. Reducing costs and improving profitability

APS software affects the cost and profitability directly by adapting to resources and production programs. Manufacturers can maintain optimal inventory levels, materials can reduce waste and prevent expensive downtime, resulting in significant savings.

Benefits of APS for cost management include:

When APS is integrated with ERP solutions for manufacturing, managers receive detailed insights into production costs, physical use and labor expenditure. This visibility allows for better financial planning and strategic decisions that increase overall profitability.

6. Role of custom ERP software in manufacturing

While standard ERP solutions meet general business requirements, custom ERP software provides a tailored approach for manufacturers. Custom system APS modules can be specially designed for shop floor operations, aligning software functionality with real workflows.

Custom ERP software benefits include:

By combining APS and custom ERP software, manufacturers can create a composite system that supports an accurate scheme, effective scheduling and seamless shop floor management, eventually leading to high productivity and development.

Empowering manufacturers with TheERPHub

Advanced planning and scheduling software transforms shop floor operations by improving efficiency, visibility and control. When paired with a cloud-based ERP systems like TheERPHub, manufacturers gain centralized data management, real-time insights and scalable solutions designed to meet unique business requirements.

TheERPHub provides the best advanced planning and scheduling software and custom ERP solutions that help manufacturers optimize production, reduce costs and improve profitability. For businesses looking to enhance their shop floor operations and drive sustainable growth, explore us today and experience the power of intelligent manufacturing. Contact us to learn more.