Blog Detail

Maximizing Manufacturing Efficiency with Production ERP Software

The Impact of Production ERP Software on Manufacturing Productivity

In today's rapidly changing industrial landscape, manufacturers need to seek methods to stay competitive by enhancing efficiency, minimizing waste, and optimizing production processes. One of the most effective tools at their disposal for achieving these objectives is production ERP software. By integrating various business functions such as planning, scheduling, inventory management, and quality control, production ERP systems have transformed the way manufacturers conduct their operations. In this blog, we’ll discuss how adopting production ERP can enhance manufacturing efficiency and benefit your business.

1. Grasping the Importance of Production ERP in Contemporary Manufacturing

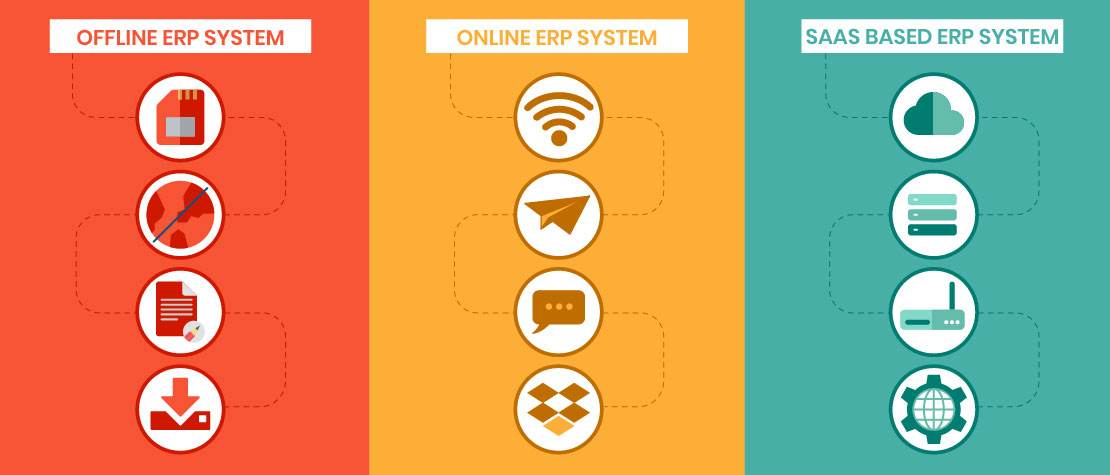

The landscape of modern manufacturing is intricate. Manufacturers face countless challenges, from supplier management and inventory control to adhering to strict timelines and maintaining product quality. Production ERP software consolidates all these functions into a single platform, enabling manufacturers to manage every facet of the production process effectively.

At the heart of a production ERP system is its capability to deliver real-time information, enhance interdepartmental communication, and automate routine tasks. This not only minimizes manual errors but also empowers teams to make faster, better-informed decisions. With a production ERP system in place, manufacturers can oversee operations throughout every phase—from sourcing raw materials to the delivery of the finished product.

By providing comprehensive visibility into operations, production ERP guarantees that resources are utilized effectively, bottlenecks are promptly detected, and processes can be modified in real time. This degree of oversight and understanding is vital for boosting both productivity and profitability in a fiercely competitive landscape.

2. Improving Precision and Efficiency with Production Planning Tools

One of the key advantages of production ERP software is its module dedicated to production planning. Successful planning serves as the cornerstone of effective manufacturing. It ensures that essential materials are accessible at the right times and that production timelines align with customer expectations and delivery plans.

By utilizing integrated production planning tools, companies can automatically generate work orders, predict material needs, and distribute labor and machinery according to real-time capacity. These characteristics remove uncertainty and avert expensive downtime or excess production. Consequently, manufacturing becomes more reliable, uniform, and economical.

In addition, sophisticated planning tools provide user-friendly drag-and-drop scheduling interfaces and Gantt charts, making it simpler for production managers to comprehend workloads and timelines. This guarantees the seamless implementation of production plans and enables proactive modifications in response to unforeseen changes and timelines. This ensures the smooth execution of production plans and allows for proactive adjustments when unexpected changes occur.

3. Real-Time Oversight with Production Management Software

In any manufacturing environment, real-time oversight is crucial for maintaining control and ensuring that output adheres to quality standards. Production management software, a fundamental element of production ERP, offers this capability. It enables supervisors to monitor the progress of each task in real time and receive notifications regarding delays, discrepancies, or equipment failures.

This immediate feedback loop empowers manufacturers to swiftly address issues, reduce waste, and ensure production remains efficient. It also fosters accountability, as team members understand that every action is being monitored and assessed. Over time, this results in enhanced performance and a mindset of continuous improvement.

Moreover, by integrating production data with other business areas such as procurement, finance, and inventory, production management software cultivates a more agile and responsive manufacturing environment. This guarantees that every decision is based on data and aligned with overarching business objectives.

4. Minimizing Expenses and Waste through Effective Resource Management

Manufacturers are continually looking for methods to reduce production expenses while maintaining quality. Production ERP software assists in this by enhancing the utilization of resources, be it raw materials, labor, or equipment. Improved planning and scheduling features enable businesses to decrease idle time, prevent stock shortages, and cut down on excess inventory.

Reducing waste is another significant advantage. By enhancing process control and monitoring quality, production ERP detects inefficiencies at an early stage. Whether it's a recurring machine issue or an ineffective workflow, the system offers actionable insights that assist in addressing problems before they escalate.

Over time, these efficiencies result in considerable cost savings. Decreased operating expenses, enhanced output, and improved inventory turnover directly contribute to a healthier financial outcome. For companies looking to grow, these benefits are not only advantageous—they are crucial.

5. Enhancing Coordination and Communication in the Supply Chain

A smooth supply chain is vital for effective manufacturing. Disruptions or miscommunications with suppliers can result in halted production, missed deadlines, and unhappy customers. Production ERP software improves supply chain management by providing comprehensive visibility throughout the entire production process.

The software guarantees that all parties are aligned, from acquiring materials to fulfilling orders. Automated purchase orders, inventory updates, and supplier alerts facilitate communication and reduce mistakes. Additionally, integrated demand forecasting aids businesses in ordering the correct quantity of materials at the optimal time, preventing both overstocking and stock shortages.

Improved coordination also leads to stronger relationships with both suppliers and customers. By offering precise delivery schedules, consistent quality, and prompt communication, your company positions itself as a more dependable and desirable partner within the supply chain network.

6. Enhancing Decision-Making through Data-Driven Insights

In the manufacturing sector, every moment and every choice are crucial. One of the key advantages of production ERP is its capability to deliver comprehensive reports and dashboards that enable leaders to make quick, informed decisions. Whether it's tracking key performance indicators (KPIs), evaluating production trends, or predicting future demand, the information produced by the system is essential.

By utilizing these insights, production managers can optimize processes, pinpoint high-performing teams, and tackle areas that are not meeting expectations. The system's analytics also facilitate long-term strategic planning by uncovering trends that may not be visible through manual monitoring.

Having a centralized data source prevents data silos and guarantees that all departments—from production to finance to sales—are utilizing the same accurate, real-time information. This cohesive strategy enhances collaboration, transparency, and overall business agility.

TheERPHub—Your Ally in Production Efficiency

In the current competitive landscape of manufacturing, achieving efficiency is not merely an objective—it’s essential. Adopting a robust ERP system for production is the most strategic move a manufacturer can make to maintain a competitive edge. From optimized production planning to use comprehensive production management software, the appropriate ERP solution streamlines operations, minimizes waste, improves quality, and increases profitability.

TheERPHub focuses on delivering customized production ERP software solutions that meet the unique requirements of manufacturers across different sectors. Our platform is designed to support your entire production process, featuring advanced tools, real-time insights, and powerful analytics—all integrated into one solution.

Enhance your manufacturing productivity by advancing to the next level. Reach out to us now for a personalized demonstration and see how our production ERP can revolutionize your operations.